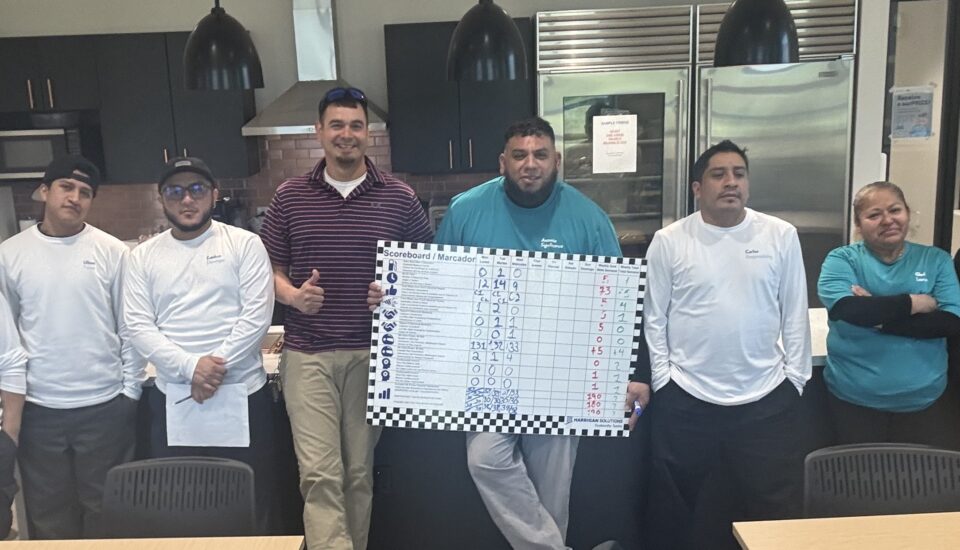

Building Trustworthy Sanitation Teams

May 13, 2025

How We Drive Profit for Our Customers

July 15, 2025The Big Idea: Continuous improvement (Kaizen) in food sanitation doesn’t start with production numbers – it starts with people. Specifically, Trustworthy Teams empowered through leadership, autonomy, and purpose.

Why It Matters: In food processing environments, where compliance and cleanliness are non-negotiable, deliberate leadership practices and the strength of your workforce determine your success. Growth-oriented teams adapt faster, catch issues earlier, and drive long-term operational improvements. But they don’t form by accident.

What Works: At Harrigan Sanitation Solutions, we’ve learned that strong leaders shape how workers see themselves. When team members feel needed for their unique strengths, they get better with every shift. That’s why we focus on creating both a culture and a system that values each person as an individual. We hire and support people in a way that affirms:

- “We are a team, and I’m needed for my unique strengths.”

- “They see me, they need me, I belong.”

- “At work, I fulfill my need to use my strengths to help others.”

Here are a few of the ways we help cultivate that mindset on the floor:

- Prime Good Feelings: Start with what’s right. Recognize individual contributions, and use language that builds confidence. Prime psychological safety.

- Manage Meaning: Always explain why it matters – whether it’s a sanitation protocol or a process improvement.

- Create Connections: Genuine relationships build trust, and trust builds accountability.

- Encourage Autonomy, Mastery, Purpose: Give workers space to own tasks, improve skills, and see the greater impact of their work.

One of the specific resources we use is the Spotter Card – a practical, people-focused framework that drives engagement, feedback, and better results on the floor.

The 7 C’s:

- Core Behavior Standards

- Clarify Expectations

- Catch the Right

- Catch the Almost Right

- Correct the Course

- Conversation that Escalates

- Celebrate Success

Along with an Ignition Card, Race Plan Prep Card, and Race Plan Questions Card, these tools form a repeatable system of giving effective feedback so that teams stay aligned and purposeful.

The Bottom Line: Fully-staffed sanitation crews engaged in Continuous Improvement reduce risk, and help realize company profit potential. If you want a workforce that consistently meets SQF, BRC, FDA, and USDA standards and contributes to continuous improvement, start by building a culture where they belong, grow, and lead.

Next Step: Want to explore how we drive continuous improvement in food sanitation? Contact us or reach Bill Harrigan at bharrigan@harrigansolutions.com.